Do you also feel that a small-scale company may not take your project well?

Let’s burst that bubble.

In the competitive world of packaging, size does not always equate to capability. Small packaging companies often possess unique strengths that enable them to excel in delivering large-scale projects.

Let’s explore why and how these nimble enterprises can outperform their larger counterparts, offering invaluable benefits to their clients looking for reliability, innovation, and superior service.

The Misconception: Bigger is Better

It’s a common misconception that larger companies are better equipped to handle significant projects. While size can bring certain advantages, it also introduces layers of bureaucracy, slower response times, and a one-size-fits-all approach. Small packaging companies, on the other hand, often thrive on agility, personalized service, and innovation, making them formidable contenders in the packaging industry.

Why Do Small Packaging Companies Excel?

Agility and Flexibility

One of the standout advantages of small packaging companies is their agility. Unlike larger firms bogged down by extensive hierarchies and rigid processes, small companies can quickly adapt to changing project requirements and market dynamics. This flexibility ensures that they can meet tight deadlines, pivot when necessary, and tailor their services to meet specific client needs.

Personalized Service

Small packaging companies pride themselves on providing personalized service. Each client is treated as a priority, with tailored solutions that reflect their unique branding and project requirements. This level of customization is often difficult for larger companies to match. By fostering close relationships with clients, small companies ensure that every project receives the attention and dedication it deserves.

Innovation and Creativity

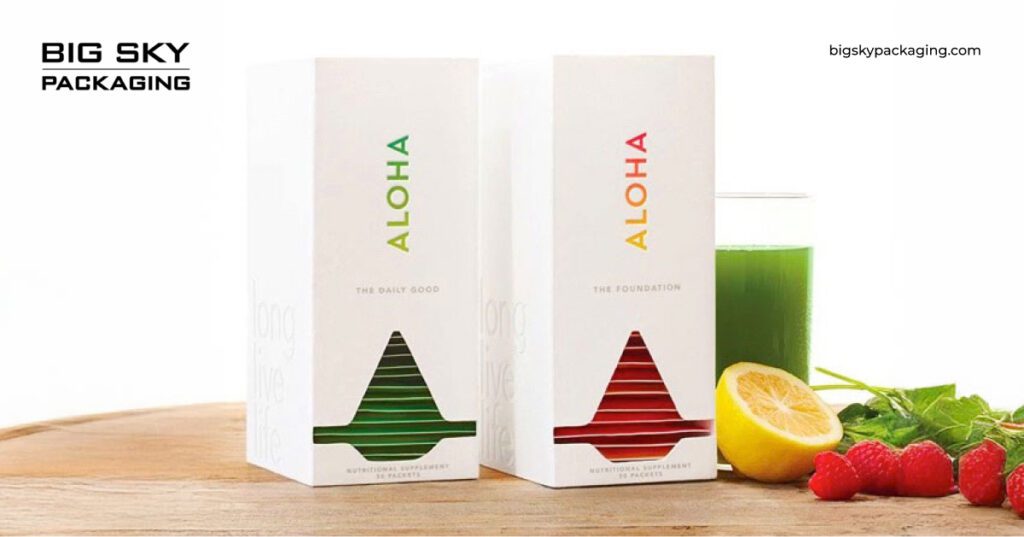

With fewer bureaucratic hurdles, small packaging companies are hotbeds of innovation and creativity. They can experiment with new materials, designs, and processes more freely, leading to groundbreaking solutions that set their clients apart in the market. This innovative spirit is crucial for delivering packaging that is not only functional but also aesthetically captivating and aligned with the latest trends.

Cost-Effectiveness

Smaller companies typically have lower overhead costs compared to their larger counterparts. This cost efficiency translates into competitive pricing for their clients without compromising on quality. B2B clients can thus enjoy high-quality packaging solutions that fit within their budget, maximizing their return on investment.

Commitment to Quality

For small packaging companies, every project is a testament to their capabilities. This drives a relentless commitment to quality. They understand that their reputation hinges on the success of each project, and they go above and beyond to ensure that the final product exceeds client expectations. This dedication often results in superior craftsmanship and attention to detail.

How Small Packaging Companies Deliver Large-Scale Projects

Advanced Technology and Tools

Embracing advanced technology and tools is one-way small packaging companies level the playing field. From state-of-the-art design software to automated manufacturing processes, these companies invest in the latest technologies to enhance their efficiency and output. This technological edge ensures that they can handle large volumes without compromising on quality or timelines.

Scalable Operations

Small packaging companies design their operations to be scalable. This means they can ramp up production quickly to meet the demands of large projects. By maintaining a flexible and scalable infrastructure, they can take on significant projects with the confidence that they can deliver on time and within budget.

Agility and Flexibility

One of the standout advantages of small packaging companies is their agility. Unlike larger firms bogged down by extensive hierarchies and rigid processes, small companies can quickly adapt to changing project requirements and market dynamics. This flexibility ensures that they can meet tight deadlines, pivot when necessary, and tailor their services to meet specific client needs.

Personalized Service

Small packaging companies pride themselves on providing personalized service. Each client is treated as a priority, with tailored solutions that reflect their unique branding and project requirements. This level of customization is often difficult for larger companies to match. By fostering close relationships with clients, small companies ensure that every project receives the attention and dedication it deserves.

Innovation and Creativity

With fewer bureaucratic hurdles, small packaging companies are hotbeds of innovation and creativity. They can experiment with new materials, designs, and processes more freely, leading to groundbreaking solutions that set their clients apart in the market. This innovative spirit is crucial for delivering packaging that is not only functional but also aesthetically captivating and aligned with the latest trends.

Cost-Effectiveness

Smaller companies typically have lower overhead costs compared to their larger counterparts. This cost efficiency translates into competitive pricing for their clients without compromising on quality. B2B clients can thus enjoy high-quality packaging solutions that fit within their budget, maximizing their return on investment.

Commitment to Quality

For small packaging companies, every project is a testament to their capabilities. This drives a relentless commitment to quality. They understand that their reputation hinges on the success of each project, and they go above and beyond to ensure that the final product exceeds client expectations. This dedication often results in superior craftsmanship and attention to detail.

How Small Packaging Companies Deliver Large-Scale Projects

Advanced Technology and Tools

Embracing advanced technology and tools is one-way small sustainable packaging companies level the playing field. From state-of-the-art design software to automated manufacturing processes, these companies invest in the latest technologies to enhance their efficiency and output. This technological edge ensures that they can handle large volumes without compromising on quality or timelines.

Scalable Operations

Small packaging companies design their operations to be scalable. This means they can ramp up production quickly to meet the demands of large projects. By maintaining a flexible and scalable infrastructure, they can take on significant projects with the confidence that they can deliver on time and within budget.

Experienced Workforce

The workforce of a small packaging company is often a close-knit team of experienced professionals. This expertise allows them to manage large-scale projects with precision and efficiency. The collaborative nature of small teams ensures that every member is aligned with the project goals, contributing to a seamless and effective execution.

Client Collaboration

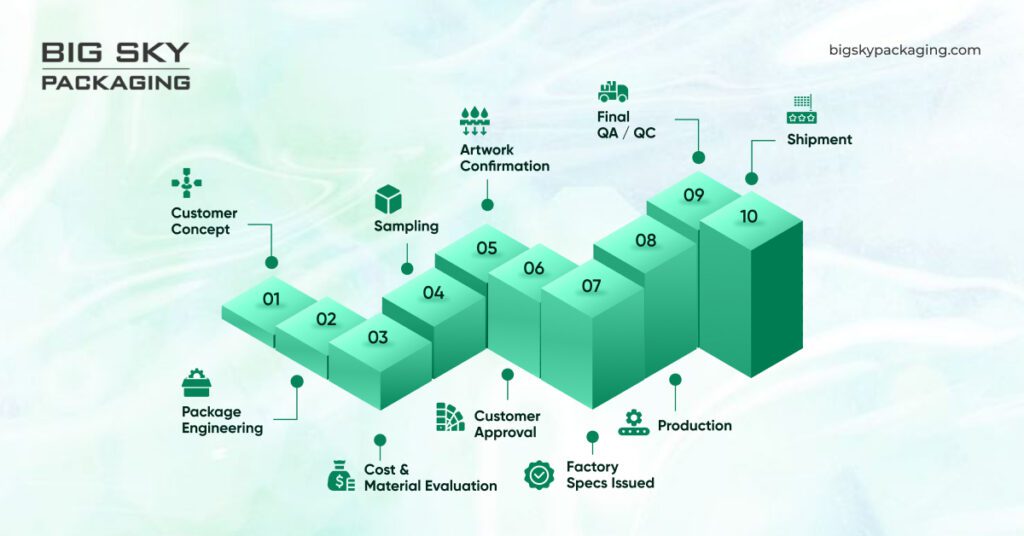

Successful delivery of large-scale projects requires close collaboration with clients. Small packaging companies excel in maintaining open lines of communication, involving clients at every stage of the project. This collaborative approach ensures that the final product aligns perfectly with the client’s vision and requirements, minimizing the risk of costly revisions and delays.

Conclusion

In conclusion, small packaging companies possess unique attributes that enable them to excel in delivering large-scale projects. Their agility, personalized service, innovation, cost-effectiveness, and commitment to quality make them invaluable partners in the B2B landscape.

At BIG SKY PACKAGING, we are delivering large-scale projects with finesse and reliability. Our commitment to innovation, personalized service, and quality has positioned us as a trusted partner for B2B clients seeking exceptional packaging solutions. We leverage advanced technology, and a dedicated team to ensure that every project, regardless of its scale, is executed to perfection.

In all, we harness these strengths to provide our clients with packaging solutions that exceed expectations and drive success. Contact us today to discover how we can transform your packaging needs into reality.

The workforce of a small packaging company is often a close-knit team of experienced professionals. This expertise allows them to manage large-scale projects with precision and efficiency. The collaborative nature of small teams ensures that every member is aligned with the project goals, contributing to a seamless and effective execution.