In B2B environments, packaging is far more than a container—it’s a strategic asset that directly influences brand performance, operational efficiency, product protection, and customer perception. When engineered thoughtfully, packaging strengthens every link of the supply chain. When it falls short, the consequences ripple through logistics, production, and customer satisfaction.

For brands relying on folding cartons and set boxes, packaging must successfully deliver on five critical roles to justify its place in the marketplace. Neglecting any one of these roles increases the risk of damaged goods, excess costs, miscommunication, or even lost business.

Below is a deeper look into these essential functions—and how BIG SKY PACKAGING ensures each one is executed flawlessly.

1. Protection and Preservation

The most fundamental responsibility of any packaging is simple: protect what’s inside. From fragile components and beauty products to premium, high-value items, structural strength is non-negotiable.

Weak materials, improper board selection, or poorly engineered closures lead to breakage, returns, and dissatisfied customers. In B2B markets—where products are filled, transported, and redistributed—the failure of a single carton can create delays, increase operational costs, and damage a company’s reputation.

How BIG SKY PACKAGING adds value:

Our structural engineers meticulously analyze material strength, closure systems, and carton geometry to ensure durability without unnecessary weight or cost. Through drop testing, compression analysis, and real-world performance evaluation, we design packaging that reduces damage rates and keeps supply chains running smoothly.

2. Operational Efficiency and Supply Chain Fit

Packaging should never slow down production. It must ship flat, stack efficiently, assemble quickly, and integrate seamlessly into automated or manual packing lines.

When boxes require excessive adjustment or don’t align with equipment, throughput drops, errors increase, and labor costs rise. In high-volume B2B settings, these inefficiencies compound rapidly.

Where BIG SKY PACKAGING makes the difference:

We engineer cartons with line efficiency in mind—reducing assembly complexity, optimizing dimensions for palletization, and ensuring compatibility across various equipment types. Our designs reduce setup time, minimize waste, and help brands maintain consistent, cost-effective fulfillment processes.

3. Brand Communication and Differentiation

Even in B2B markets, packaging is a powerful communication tool. It signals quality, professionalism, and brand identity long before the product is handled. Tactile finishes, premium materials, and refined structural design reinforce the value of what’s inside.

Packaging that looks generic or low-tier can unintentionally diminish the perceived worth of the product, impacting retailer confidence, wholesale conversions, or end-customer trust.

How BIG SKY PACKAGING elevates brands:

We create cartons and set boxes that function as brand assets. From foil stamping and embossing to unique textures and custom structures, we help brands express their identity with clarity and distinction. Every touchpoint becomes an opportunity to strengthen recognition and build trust.

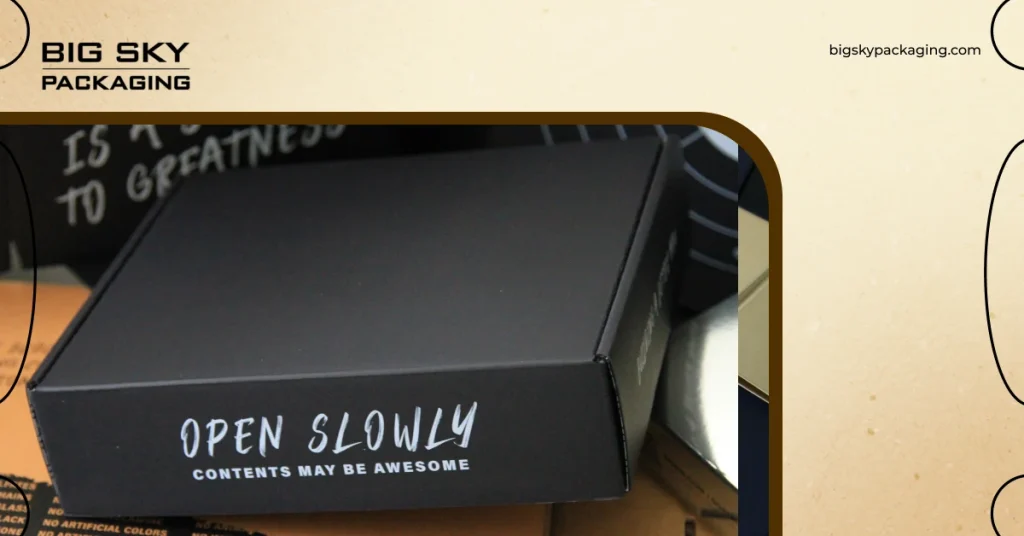

4. Marketing Utility and Unboxing Experience

Unboxing matters—even in B2B. Whether the package is opened by a retailer, distributor, warehouse worker, or direct customer, the experience communicates expectations about the product and the brand.

Smooth-opening structures, clear internal organization, and protective inserts reduce the risk of damage and rework downstream. When packaging is intuitive and polished, it enhances product presentation and supports repeat purchasing behavior.

BIG SKY PACKAGING’s contribution:

We design packaging that enhances visibility, improves handling, and delivers a consistently positive unboxing experience. Clean seams, efficient closures, and thoughtful inserts help products ship safely and shine on arrival.

5. Sustainability and Lifecycle Responsibility

As environmental regulations expand and corporate responsibility expectations rise, packaging must meet sustainability standards without sacrificing performance. Material selection, weight reduction, and recyclability all influence a brand’s environmental footprint.

Brands that fail to align their packaging with sustainability expectations may face buyer resistance, increased regulatory scrutiny, or reputational risk.

BIG SKY PACKAGING’s sustainability leadership:

We help brands adopt responsible materials—FSC-certified boards, recycled substrates, mono-material solutions—and packaging engineer structures that reduce waste at every stage. Our sustainability audits identify opportunities to improve recyclability, decrease carbon impact, and align packaging with modern environmental goals.

How Packaging Engineers Strengthen Box Performance

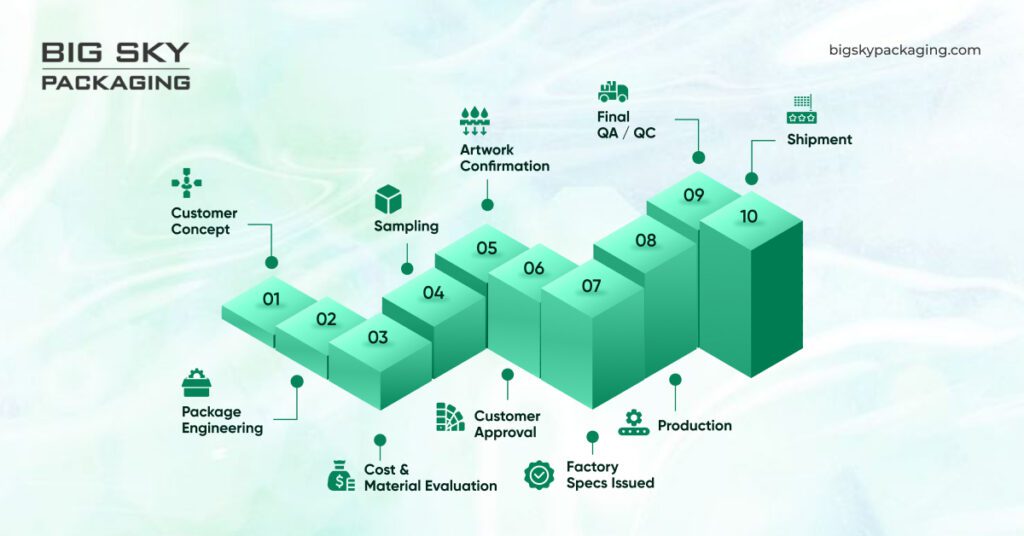

At BIG SKY PACKAGING, our team brings together engineering, design, sustainability, and production expertise to ensure your packaging performs across all five essential roles. We provide:

- Structural analysis and testing

- Material evaluation and optimization

- Print and finish development

- Sustainability strategy and lifecycle assessment

- Global manufacturing and logistics support

By partnering early in the development process, we help brands avoid common pitfalls—under-engineered structures, high labor costs, inconsistent branding, and environmentally inefficient materials. Our solutions balance performance, cost efficiency, and aesthetics with precision.

Whether you need folding cartons for cosmetics, premium rigid boxes for retail, or supply-chain-optimized packaging for distribution, BIG SKY PACKAGING delivers solutions that reinforce your brand and enhance operational performance.

Conclusion

In B2B markets, packaging is more than a box—it is a protector, facilitator, communicator, marketer, and sustainability driver. Brands that excel in all five areas gain measurable advantages across cost, efficiency, brand perception, and customer experience.

With BIG SKY PACKAGING as your partner, packaging becomes a strategic investment in performance, perception, and long-term growth—not a cost center.

Frequently Asked Questions

Strong structural design helps cartons withstand shipping stresses, reducing damage rates and minimizing costly returns.

Premium materials, finishes, and graphics reinforce brand professionalism and elevate product perception from manufacturer to end user.

Absolutely. With engineered materials, optimized structures, and responsible supply-chain decisions, packaging can meet performance requirements while supporting sustainability goals.