In the premium wine category, the moment a customer opens the package has become just as important as the moment they pour the first glass. In 2026, unboxing is no longer a secondary experience — it is a powerful validation point that confirms whether the customer made the right purchase.

For luxury wine brands, unboxing is where expectation meets reality. When executed thoughtfully, it reinforces quality, craftsmanship, and value. When overlooked, it can quietly undermine even the most exceptional bottle.

Unboxing as a Moment of Reassurance

Premium wine buyers invest with intention. Whether the purchase is made for personal enjoyment, gifting, or collection, there is an unspoken question at the heart of every luxury transaction:

Was this worth it?

The unboxing experience answers that question immediately.

Before the label is studied or the wine is tasted, customers engage with structure, materials, and presentation. A well-considered unboxing signals that the brand understands the significance of the purchase and respects the customer’s investment.

Packaging That Confirms the Price Point

In luxury wine, perceived value must align with price — and packaging plays a defining role in that alignment.

Unboxing elements that elevate perception include:

These details work together to confirm that the wine belongs at its price point. When the experience feels elevated, the customer’s confidence in their purchase increases — even before tasting begins.

– Substantial yet refined structures that feel deliberate

– Materials that communicate quality without excess

– Protective components that cradle the bottle with care

– Clean, intuitive opening sequences that feel composed and intentional

Emotional Impact Drives Brand Loyalty

Unboxing is a tactile, emotional interaction. It slows the moment, creating anticipation and focus. For premium brands, this pause is an opportunity to build connections.

A memorable unboxing experience:

– Signals craftsmanship and restraint

– Encourages sharing and word-of-mouth

– Deepens emotional attachment to the brand

In a category where many wines compete at similar quality levels, emotional resonance often becomes the differentiator.

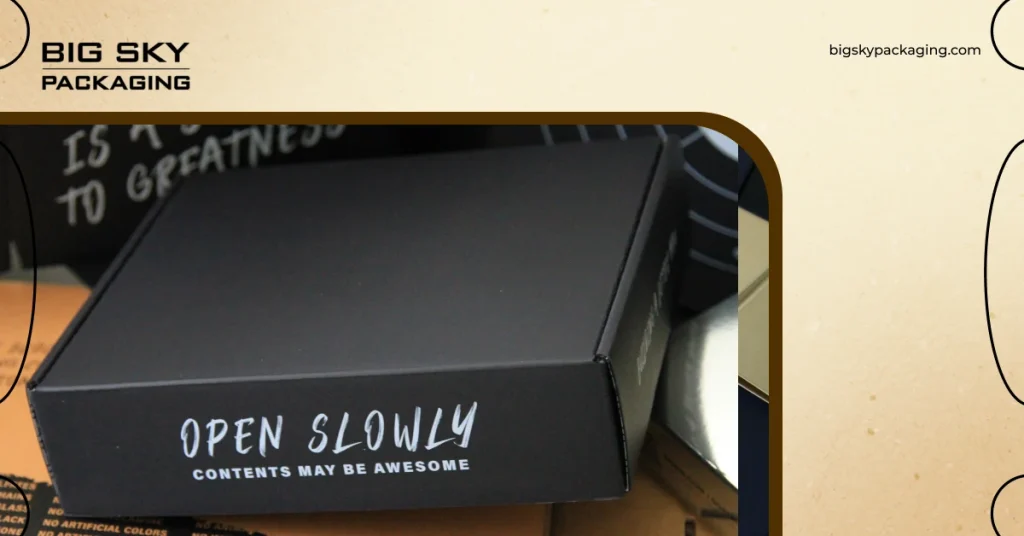

E-Commerce Has Elevated the Role of Unboxing

As premium wine continues to grow through direct-to-consumer and online channels, unboxing has become the first physical brand touchpoint.

Packaging must protect the bottle through transit while delivering a refined, cohesive experience upon arrival.

A strong unboxing experience reassures customers that quality was considered at every step — from vineyard to doorstep.

Big Sky Packaging’s Approach to Premium Wine Unboxing

At Big Sky Packaging, unboxing is treated as a critical extension of the brand — not an afterthought.

Our added value lies in aligning structure, materials, and presentation with how premium wine is purchased and experienced. We collaborate closely with wine brands to ensure packaging:

– Reflects the character and positioning of the wine

– Enhances the experience in parallel with the wine

– Balances protection, usability, and refined aesthetics

– Balances protection, usability, and refined aesthetics

With decades of experience supporting premium and luxury brands, we understand that successful unboxing is engineered through intention. Every fold, surface, and interaction is designed to reinforce trust and perceived value.

Turning Unboxing into Brand Validation

In 2026, premium wine buyers are not just purchasing a bottle — they are investing in an experience. The unboxing moment is where that investment is either validated or questioned.

When packaging feels thoughtful, composed, and aligned with the wine inside, it reassures the customer that their spend was justified. It strengthens brand perception and sets the stage for loyalty, advocacy, and repeat purchase.

For premium wine brands, unboxing is no longer optional. It is a defining moment — and when done well, it quietly confirms that the brand belongs in the luxury conversation.

At Big Sky Packaging, we help premium wine brands turn unboxing into a meaningful extension of their story — one that protects, elevates, and validates every bottle.