5 Essential Steps to Choosing the Perfect Applicator for Your Liquid Formulas

- 2 July, 2025

- 3 minutes

Because performance begins at first contact.

In the beauty and personal care industry, the applicator is no longer just a delivery mechanism—it’s an extension of the product itself. It defines user experience, elevates brand identity, and often determines how a formula performs on the skin. For liquid formulas—think serums, foundations, oils, and treatments—the wrong applicator can diminish the product’s perceived value, interfere with dosing precision, or compromise hygiene standards.

Brands operating in this space must approach applicator selection not as an afterthought but as a strategic imperative. An ideal applicator marries function with form, offering ease, elegance, and consistency while reinforcing the brand’s commitment to both innovation and user satisfaction.

Today, this also means aligning with sustainable beauty packaging goals—selecting applicators that are not only high-performing but also designed with eco-conscious materials, refillability, and recyclability in mind.

Here are the five essential steps to ensuring your next liquid formula is matched with the perfect applicator:

1. Define Your Formula’s Viscosity and Sensitivity

Not all liquids are created equal. The first step is understanding your product’s texture and behavior—whether it’s a watery essence or a viscous serum. Applicator compatibility with viscosity ensures seamless dispensing and prevents waste or mess. Products with active ingredients may also require airless systems or specific applicator tips to preserve efficacy.

2. Consider Precision and Application Zones

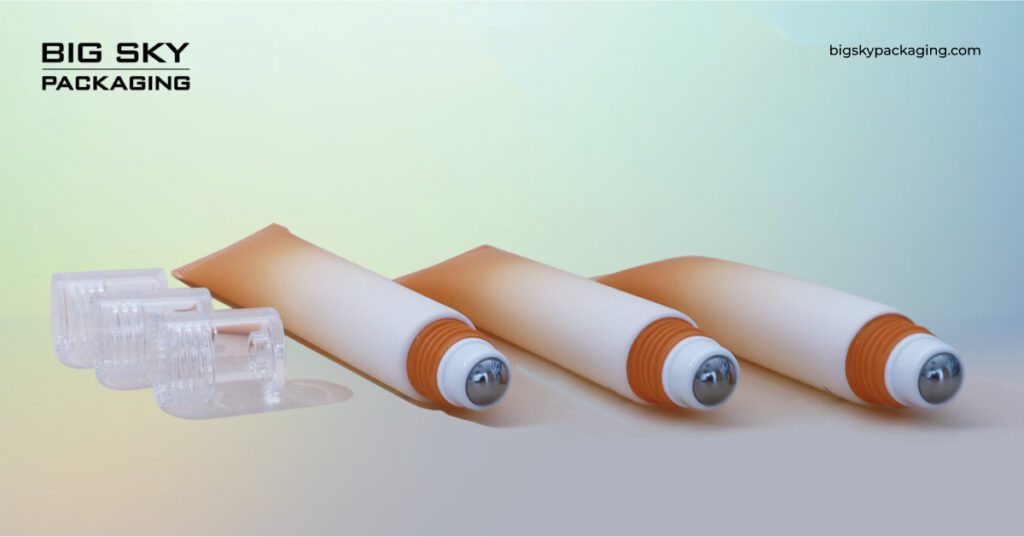

Is your product meant for targeted application—like under the eyes—or for broader use across the face or body? The geometry of the applicator tip, from flocked wands to droppers to roller balls, must reflect the precision (or coverage) required. This choice impacts user experience and plays a role in consumer satisfaction and repeat purchase behavior.

3. Align the Aesthetic with Brand Identity

Applicators are often the first tactile point of engagement. The applicator must visually and ergonomically reflect that identity, whether your brand leans clinical, luxurious, or clean beauty-focused. Every detail contributes to a unified brand story, from metallized finishes to minimal, soft-touch matte styles.

4. Factor in Sustainability and Recyclability

Sustainability is no longer optional—it’s expected. Brands must evaluate if the applicator can be refilled, recycled, or produced using biodegradable or mono-material designs. Reaching out to a beauty packaging company for forward-thinking engineering solutions is key to creating an applicator that is both elegant and eco-conscious.

5. Test, Iterate, and Validate

Before committing to production, rigorous testing is essential. Application feel, cap fit, formula flow, leakage tests, and consumer trials help ensure the applicator performs flawlessly in real-life scenarios. Investing in this phase minimizes costly revisions and strengthens product confidence at launch.

How Can Packaging Engineers at BIG SKY PACKAGING Help?

At BIG SKY PACKAGING, we understand that the perfect applicator isn’t pulled from a catalog—it’s engineered. Our team collaborates closely with brands to prototype, test, and refine applicator systems tailored to both product performance and brand vision. From concept to commercialization, we craft solutions that enhance both the formula’s delivery and the user’s experience.

Frequently Asked Questions

The right applicator ensures precise dosing, enhances user experience, and maintains product integrity, which is key to consumer satisfaction and brand trust.

Yes, through smart engineering—like mono-material builds, refillable formats, or reduced components—sustainability and functionality can go hand in hand.

Ideally, it should start alongside formula development to ensure seamless compatibility and reduce costly design revisions later.